MUDROOM LOCKER SYSTEM - The Design

Work with the Customer

Communicate Efficiently and Clearly

Communicate Efficiently and Clearly

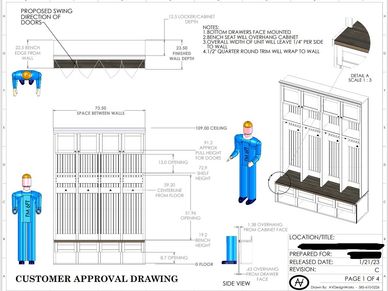

Using your sketches, or pictures from other things you've seen, we create Approval Drawings to clearly communicate the design. This locker unit will be built into an alcove in the customer's home so all sides & back will be obscured with walls.

Communicate Efficiently and Clearly

Communicate Efficiently and Clearly

Communicate Efficiently and Clearly

The Customer is part of the Design Process and can share input and suggestions that develop into real drawings for approval.

Customer Approval Drawing

Communicate Efficiently and Clearly

No Surprises and you get just what you want

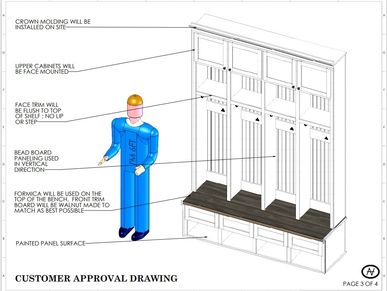

See the project with simulated colors and wood grains to get a better idea of finished product.

No Surprises and you get just what you want

No Surprises and you get just what you want

Customers agree on every aspect of their build and when final approval of the build drawings are complete, we MAKE IT REAL!

Shipping Logistics

Shipping Logistics

Having all the designs in a 3D CAD system we are able to plan shipping in available trailers or U-haul rentals. This is planned to be moved inside this 6'x6' enclosed trailer volume represented in transparent blue.

The Build

Rough cut Ash boards are refined to exact dimensions per the build drawings to become door panels, drawer faces, and face trim. Ash was used as a stronger grain wood for attaching hinges and to withstand impacts from use over time.

Doors and drawer faces are made early and predrilled for all hardware.

Drawers are assembled with glued slotted joints on a flat surface plate. Floating bottom is captured in slots to allow for any material expansion.

Bench panels are all glued and screwed so all fasteners are obscured from view in the assembly. A Walnut accent strip is attached to the front of bench to compliment the Walnut laminate top and provide protection from laminate chipping. Ash face trim has been applied to all panel ends.

The process of applying the Walnut laminate sheeting begins. It's a bit nerve racking and demands much attention to detail using the right tools to ensure a good trimmed fit and a solid adhesion. Contact cement is a very unforgiving adhesive if positioned incorrectly.

The construction of the upper Locker Unit has begun. The assembly process must be planned out so that every panel connection can be secured strongly and in an order in which screws are concealed as the assembly progresses. So that later shelves and openings are all square, there are a few tricks that can be implimented with some careful thought and patience.

Care is taken to clamp every connection with glue and hold in position while fasteners are put in place.

Ash face trim is glued and clamped in place and left for hours before clamps are removed. Intersections are sanded, filled for any voids, and sanded again.

In the Bench, drawer slide mounts are custom fit in each position so that their thickness exactly matches the offset of the face trim. The soft close drawer slides will transition to the face trim and be mounted on these strips so the faces must be flush.

Kilz sealer paint is applied to all horizontal pine slats so that knots will never come thru in the years to come. Then everything is covered with primer and two coats of semi-gloss white paint.

Walnut laminate is covered with construction paper to protect from scratches and the paint process is applied to the inside of the bench.

All drawers are installed in bench and every upper cabinet door swing, knob, and hook is installed exactly as shown in the customer's approval drawing. Bottom panel sheet attached to the bottom of this locker unit is only there to provide stability during shipping.

Everything is Ready to Ship!

This website uses cookies.

Please Accept, that way I can see what you're interested in and show more of it! Thanks!!